Need a Gear Quote? Here’s What We Need to Know

Here’s the scenario: You’re tasked with finding a supplier for a gear or gearing set for a new project at your company. You hop online and start researching gear manufacturing companies, and narrow the field based on things like capabilities, manufacturing and engineering services, market expertise, quality certifications, and reputation. Now you’re ready to reach out to your top choices and request quotes to compare prices.

But wait, not so fast. Do you have enough information to give to your potential gear manufacturer to ensure you receive a quick and accurate quote?

To take the worry and frustration out of the gear quoting process and help you meet your deadlines, we’ve assembled an outline of the essential information gear manufacturers need in order to provide a quote.

Essential Information for Obtaining a Gear Quote Company and Contact Information

While this information isn’t necessarily essential for quoting, it is definitely helpful to ensure the process goes smoothly. By providing your full company and contact information up front, the gear manufacturer can easily contact you if any additional information is required, and then quickly record, generate, and send your quote to you.

Quantity

It goes without saying that quantity is a huge factor in quoting gears, but we’ll say it anyway. Gear manufacturers can often offer reduced pricing per piece on large volume orders, while single or low volume orders may carry a larger price tag

Material

Gears can be made out of all sorts of materials, so it’s necessary to specify the gear material when requesting a quote. Different materials range in cost both by the material itself, and also the cost of manufacturing, so this information is definitely essential.

Processes

It’s important to let the gear manufacturer know if any special processes are required on your gears, as that could affect both the price and lead time on the quote. Processes could include things like heat treating and other gear finishing processes.

Quality Level

You should also let the gear manufacturer know if a certain gear quality level is required. Many manufacturers will follow any quality standard as specified, but it is important to know the expected quality level during the quoting process in case any specialized machinery or extra inspection processes are needed.

Other Customer Requirements

Every gear design is different, and additional information required for quoting and manufacturing may vary by project. Other customer requirements gear manufacturers may need include things such as delivery and post-delivery requirements, and requirements for defective material returns, if applicable.

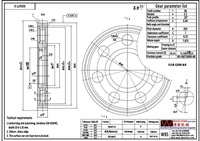

Drawings

If you have them on hand, drawings are the most efficient and effective method of providing information about your gears. In fact, most of the time, they give just about every piece of information a gear manufacturer needs to provide a quote. This includes many of the items we’ve already discussed, plus other details such as gear geometry specifications, part number, and revision level. If you can provide the drawing with your request for quote, that is definitely your best bet.

If this is a brand new gearing project and you don’t yet have a drawing, you’ll need the assistance of your gear manufacturer’s engineering department to design your gear. As a starting point for quoting, a gear manufacturer can often offer an estimated quote of the costs associated with this process, as well as actually manufacturing your gears once they’ve been designed.

If this is an existing gear but the drawing is not available, reverse engineering of your gear can provide a solution. Through reverse engineering, the gear or assembly is deconstructed in order to evaluate and analyze it. Using advanced measuring and inspection tools, engineers use this process to determine the exact geometry of your gear. From there, a copy of the original product can be manufactured. Again, this can often be quoted as an estimate up front.

It should be noted that these engineering processes can be costly, and they are not often economical if only a single gear is needed. Often, complete gear design and reverse engineering are more practical for larger volumes or recurring orders.

Gear Geometry Specifications

As we mentioned, if you don’t have a drawing, experienced engineers can either design a gear from scratch, or use reverse engineering to determine exact gear geometry. There are many essential specifications of gear geometry, and they can vary depending on the type of gear. Some of the most commonly used design specifications of a gear are:

Diametral Pitch

Pressure Angle

Number of Teeth

Helix Angle

Linear and Circular Dimensions

We should mention that this is nowhere near a complete list; in fact the list could go on and on. It is extremely important that gear design specifications are complete and accurate to ensure your gears are manufactured properly and function smoothly in their intended application. Again, we recommend consulting with an experienced gear engineer to accurately determine gear geometry if a drawing is not available.

We hope this overview gave you some good insight into the information a gear manufacturer needs in order to provide a quote on gearing projects. You may even consider bookmarking this page for future reference.

Request a Gear Quote from WhachineBrotherS

As always, the WhachineBrotherS network is here to help through every stage of the gear manufacturing process; from Inspiration to Realization. Don’t hesitate to contact us with questions at any time. We are committed to responding to your requests for quote quickly and efficiently to help you meet your goals.